VELES-AGRO

tillage equipment and spare parts

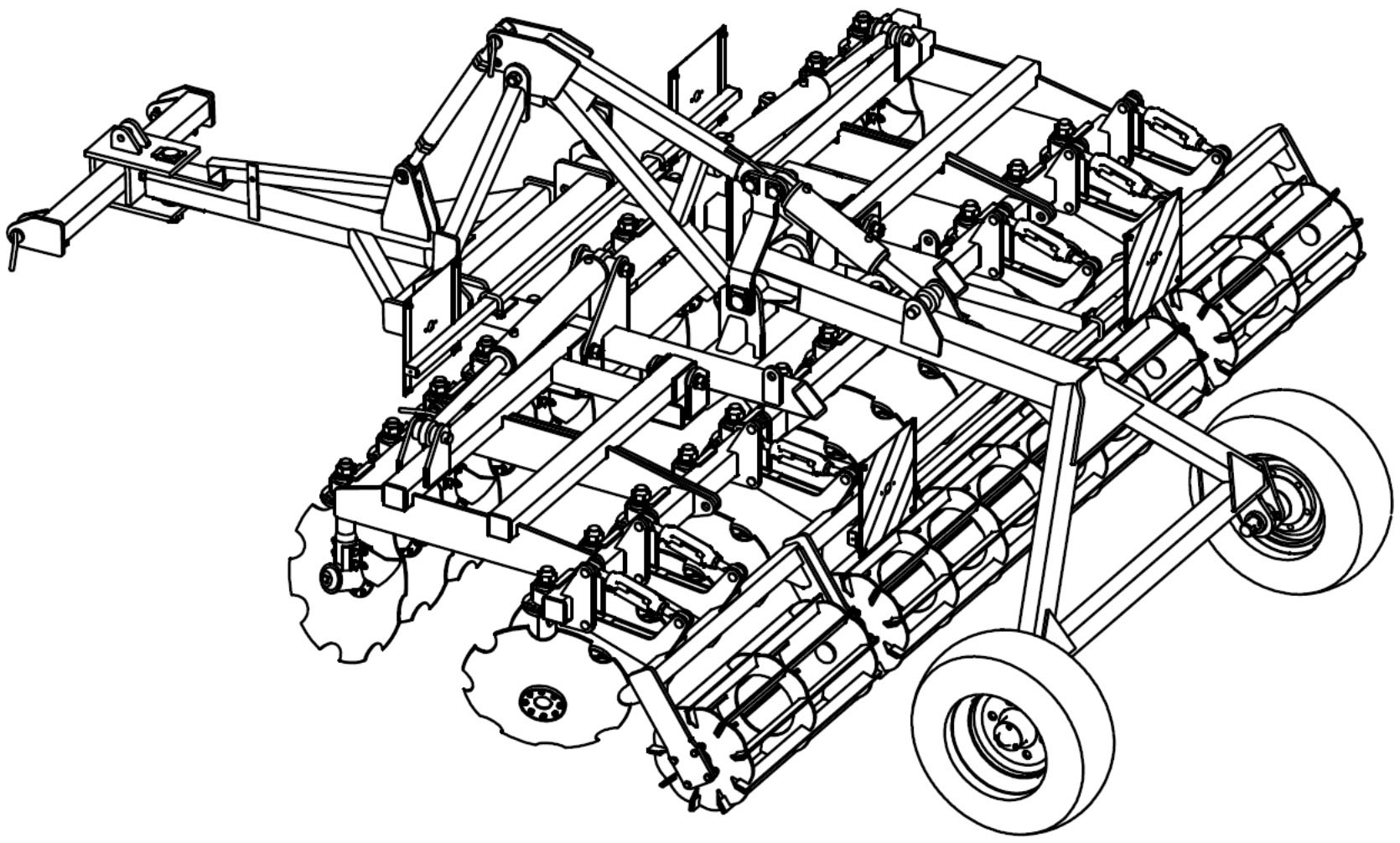

Advantages of disk harrows PD, PDM, AGN manufacture of LLC «VELES-AGRO LTD.» over similar products from other manufacturers.

4 march 2015

1. Construction of implements is made at modern level of development, allowing at the design stage to consider the dynamic and static load of projected units.

2. Company LLC «VELES-AGRO LTD» in the manufacture of implement frame structures uses square steel tubes S355JRH, Production of «Erdemir» (Turkey).

3. Sawing is made on modern foreign equipment using plasma, laser cutting of metal, band saws.

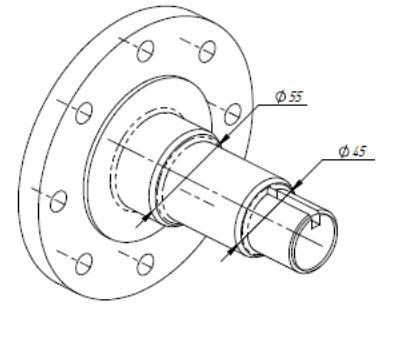

4. Turning parts produced on CNC machines with frequent handling 0,001 mm.

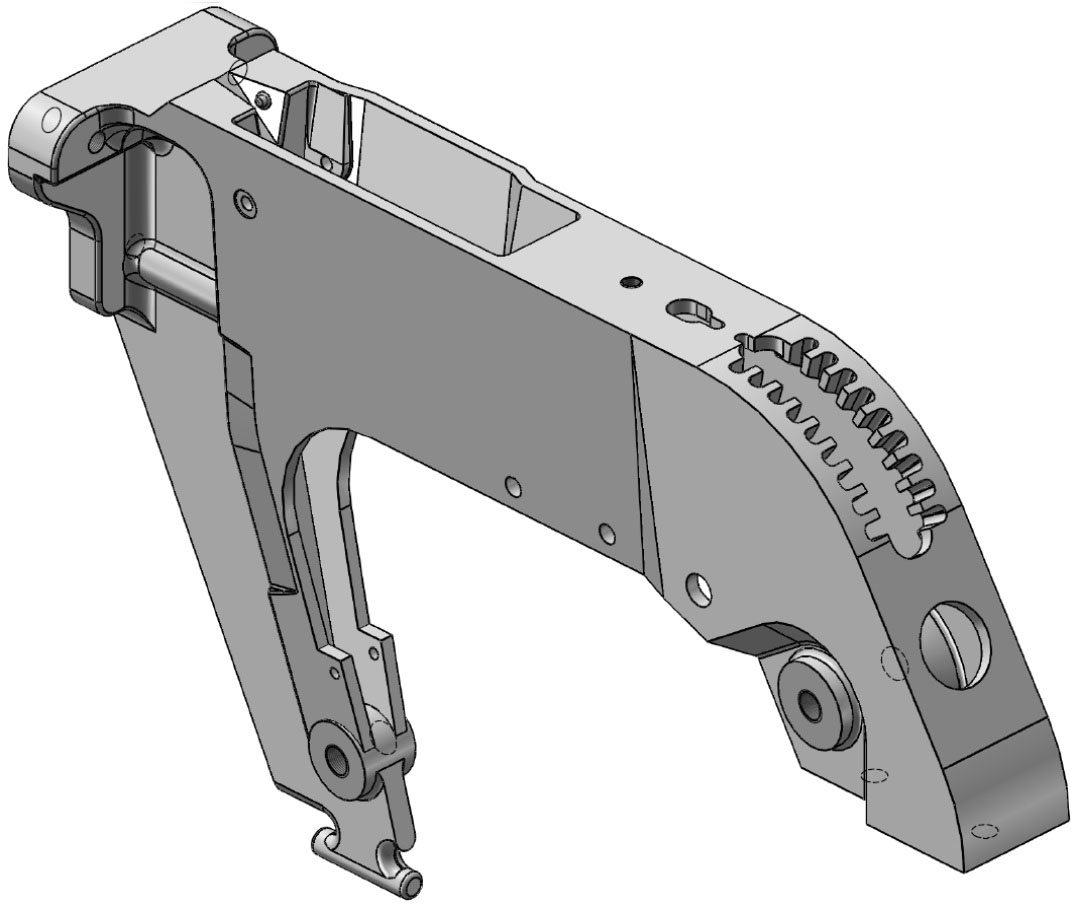

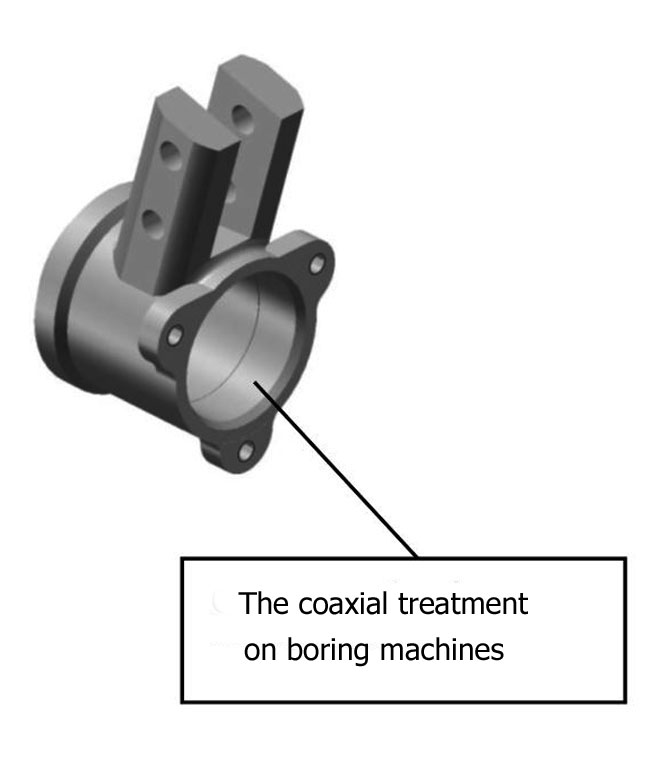

5. In the production of implements, the company uses its own foundry. Casting by burnt out models, allows to cast parts with stiffening ribs under the loads imposed on them.

6. Nodes of implements are mounted and welded in jigs, elaborated under each weldment. Conductor geometry provides exceptional welding units, excluding leashes of metal during welding and successful installation of all components on implement.

7. Welding works and semi-automatic equipment, foreign-made, in carbon environment with copper-coated wire and spray descaling.

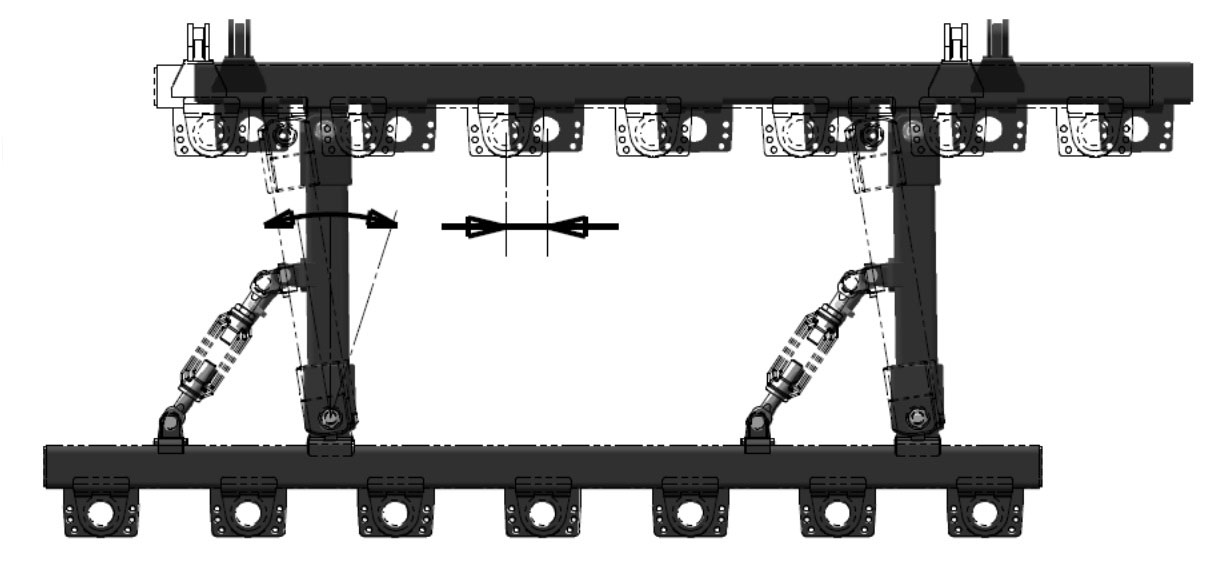

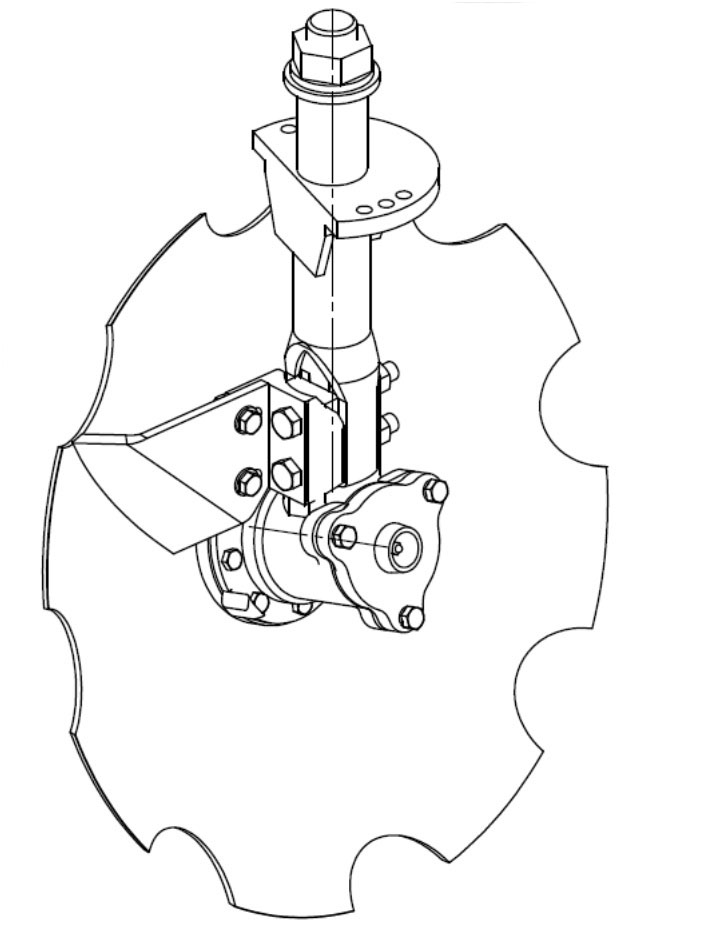

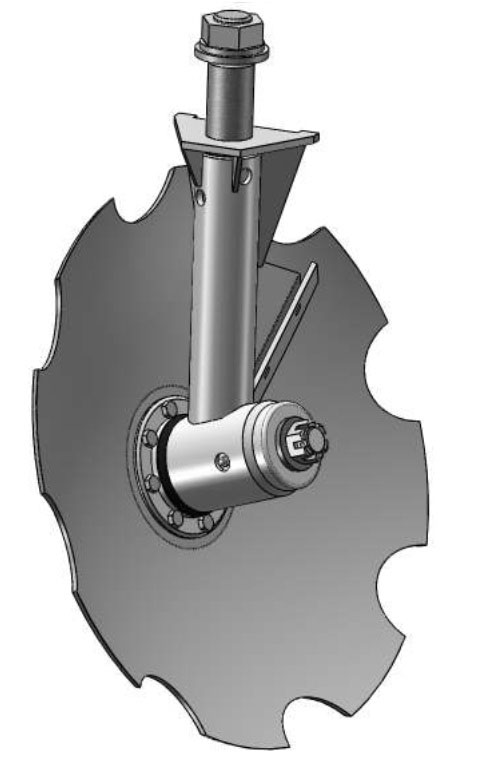

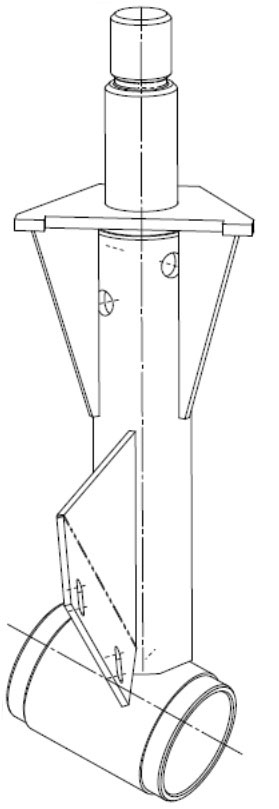

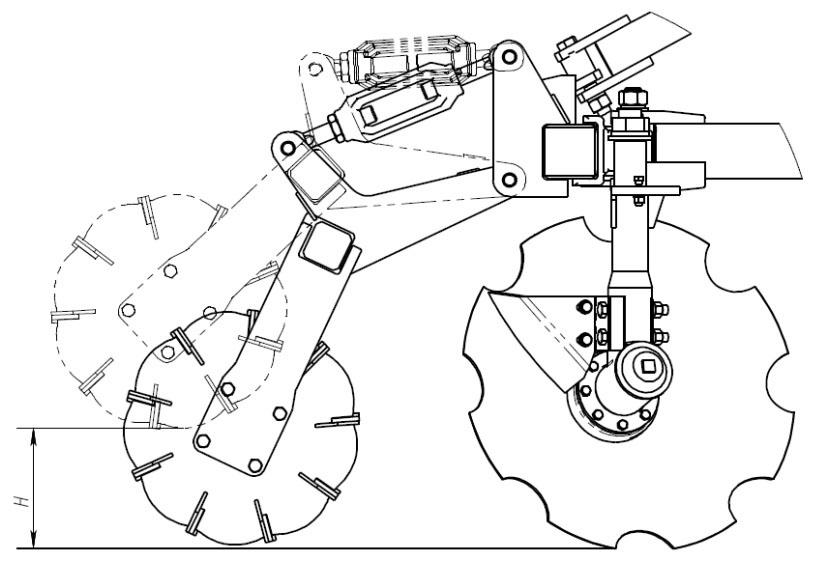

8. The basis of a stable and reliable disk units — construction of the working body. We consider in detail the working bodies of the implements LLC «VELES-AGRO LTD» and other manufacturer.

| Working body assembly VELES-AGRO | The working body assembly, other manufacturer |

|

|

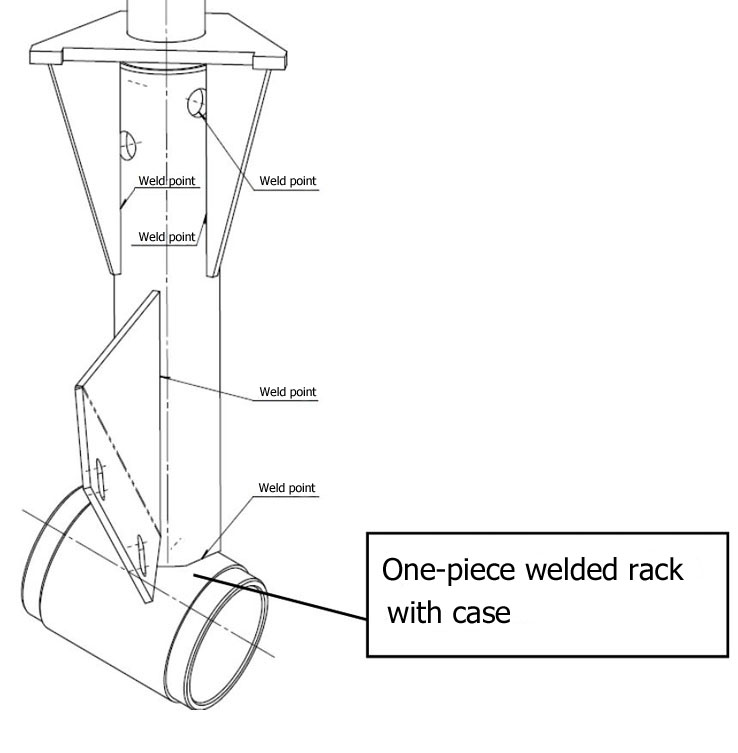

| Casted rack of working body Veles-Agro | Rack of working body in welded pipe |

|

|

| Case of the working body is formed as a separate component from the rack. Allows replacement of individual units. Fastened to the rack with two screws. | Case and rick — welded construction. At failure of one piece, changing the entire assembly. |

|

|

|

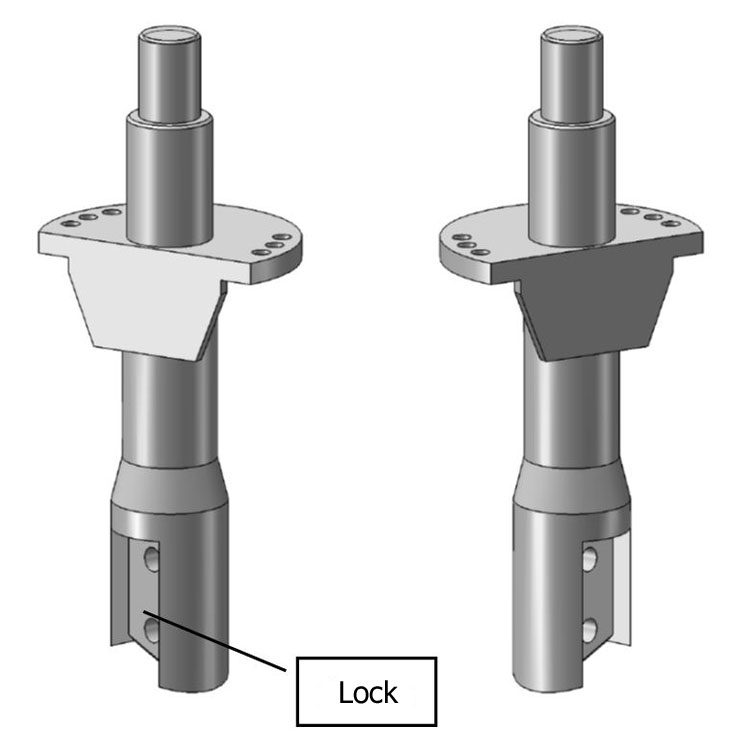

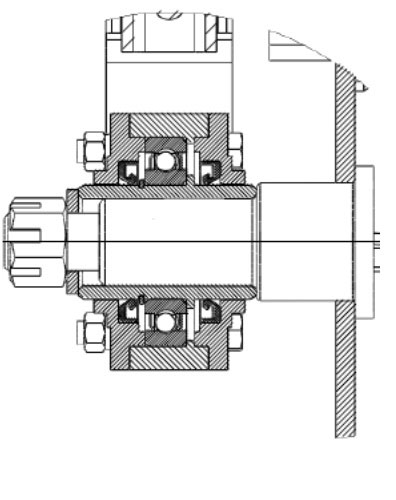

Hardened forged floor working body diameter of 45 mm and the distance to the bearing support 20 mm. Made of impact is not the type of equipment that eliminates the possibility of micro cracks. |

|

|

|

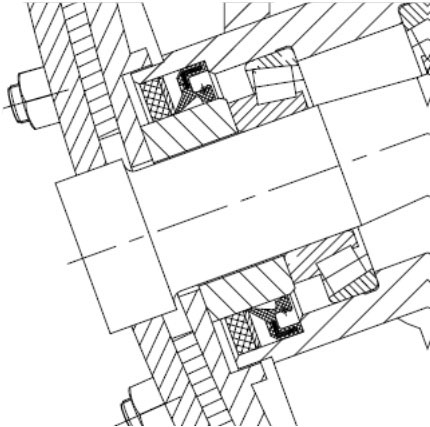

| Double lip seal on the part of the disk with a labyrinth | Standard single lip seal without labyrinth. As a consequence of wear cuffs and dirt. |

|

|

| Cleaning the cage in rotation with the disk its projections reduces the pressure of the flow of ground penetrating deep into the body. | Lack of cleaning the cage leads to failure of the lip seals and as a consequence, the destruction of the bearing assemblies. |

|

|

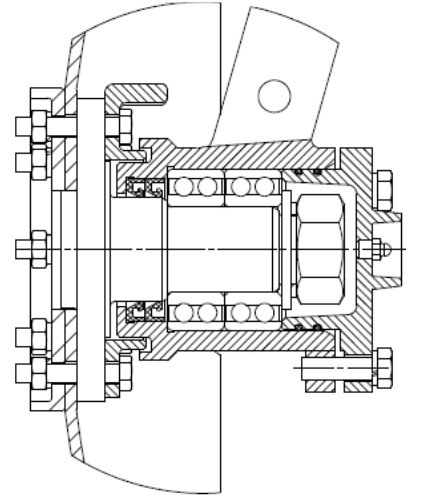

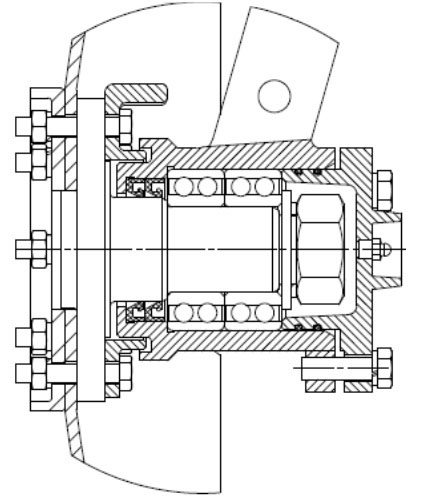

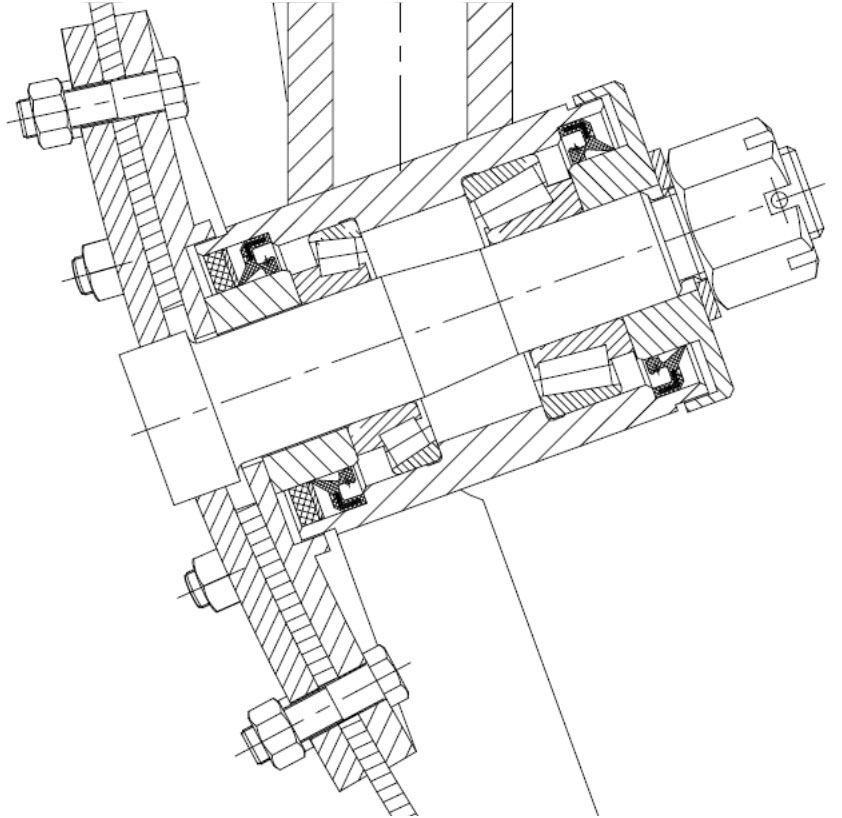

| In the case of the working bodies used ball double row angular contact bearings. These bearings carry both axial and angular load is characteristic of the disk units. Ball bearings are not squeezed out of the working chamber of the grease, as a consequence, reduced routine maintenance work. | Tapered bearings are used they do not carry the overhung loads. Tapered roller bearings plane pushes the grease from the work area and requires monthly replacement lubricant. Roller bearings tend to shrink, leading to a backlash in the work of the working body and periodic. |

|

|

|

The end of the working body of the lid closed wide with seals against dust and mortise nipple for maintenance. Axle nut is inside the body, has easy access for maintenance and adjustment. Over 5 years in 90% of cases do not require replacement. Developments are not known. In almost all cases at least 10,000 hectares. |

Body in front of the closed by metal bellow. Axle nut stands outside the housing. Not protected the body from dust and dirt. Daily lubrication and as a consequence of high consumption of fuel and working life. |

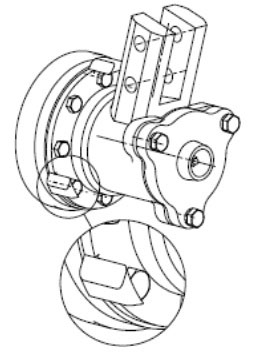

| Replacing the disk Veles-Agro takes place without removing the body. | When replacing a drive, you must disassemble the bearing assembly. |

|

|

| Drive working body Veles-Agro is made of Swedish 6 mm steel 30MnB5 (boron), has a hardness of 48?50 Rockwell units. Disks of this resource has become 3 times more than ordinary types of steel 65G. |

Apply wheels of steel ST-65G — wearing when working with abrasive soils. |

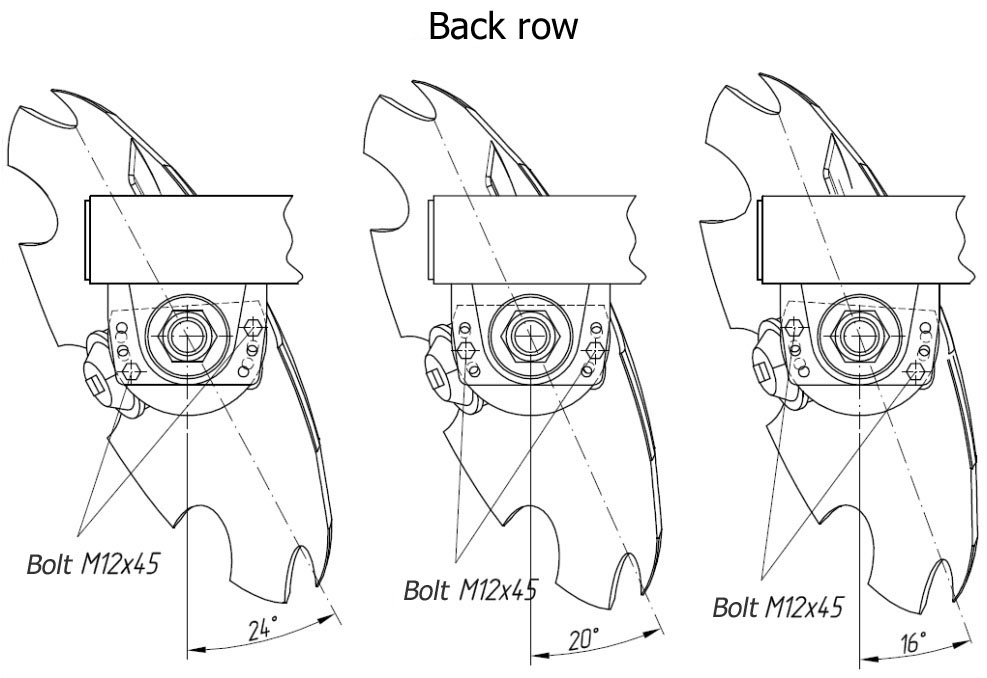

| On the frame is attached to the working body cast bracket with holes for adjusting the angle of attack changes disks16?, 20?, 24?. | Have a standard angle of attack without the possibility of adjustment for different types of soils. Or if they do, then the drilling pipe main beams, which weakens the structure of the frame. |

|

|

| Cast bracket working body has 60% girth beam frame construction; in places not weaken the structure of the frame. | Brackets consisting of weldments weaken the ability of the frame. |

|

|

|

Basic Bal Ram working bodies are made of imported spring pipe plant «Erdemir» 100x100х8 mm. |

Made of standard pipe 100x100x6 mm without spring-lasting properties. |

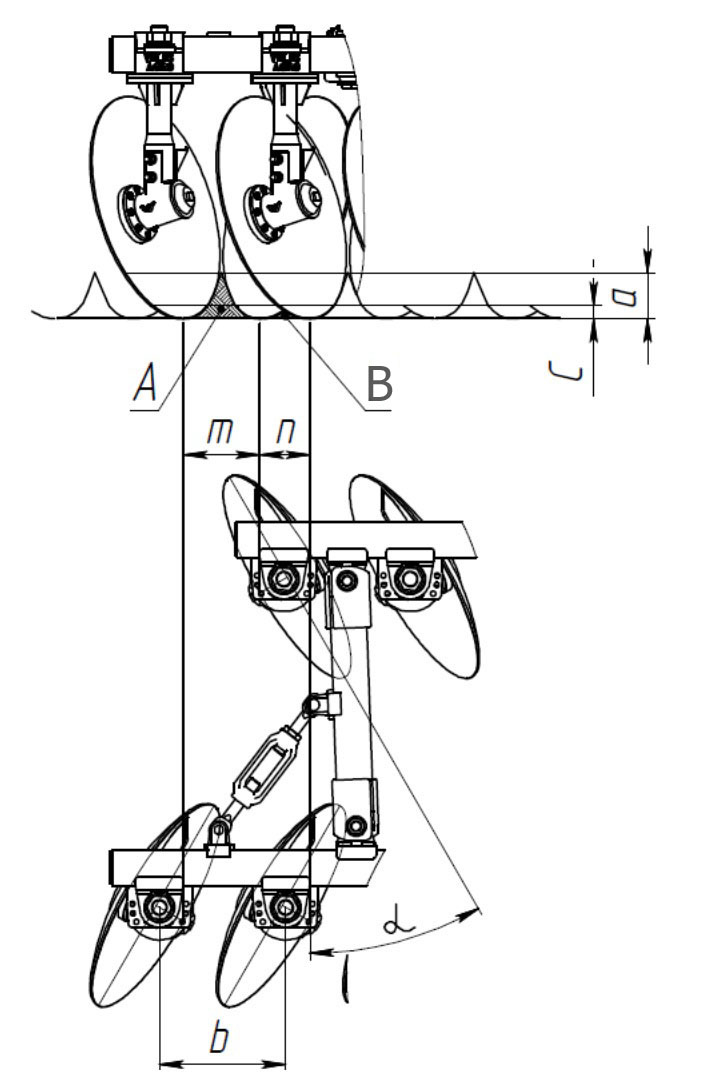

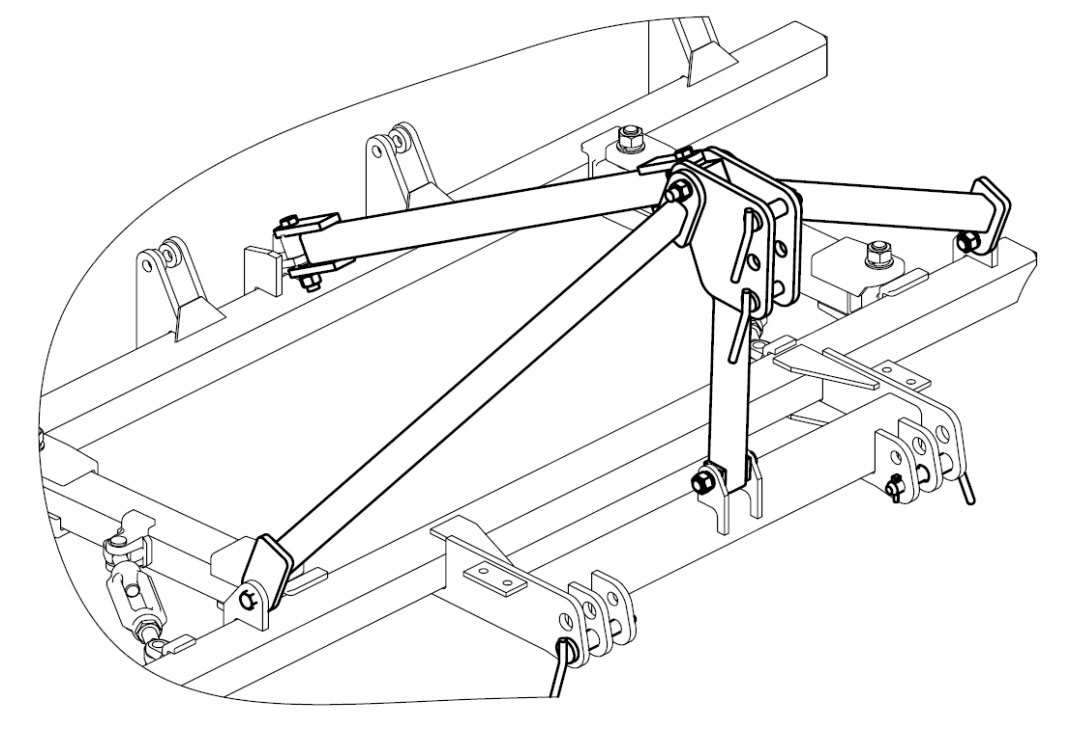

| The implements have an adjustable back beam (series PDM) allowing making the adjustment of the rear rows of discs in relation to the front. Excluding the presence of faults in the processing. | It is not always possible to adjust the quality work of the unit with a rigid frame structure. |

| Strong linkage to the tractor hitch is made of pipes 60x60x6 mm flange. | A charge of thin-walled tubes of domestic production. |

|

|

| Infinitely adjustable support-rollers as turnbuckles, allows a specified number of penetration rear disks. | Level adjustable track roller when reinstalling limiting fingers difficult adjustment process. |

|

|

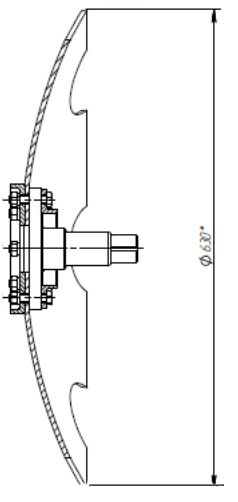

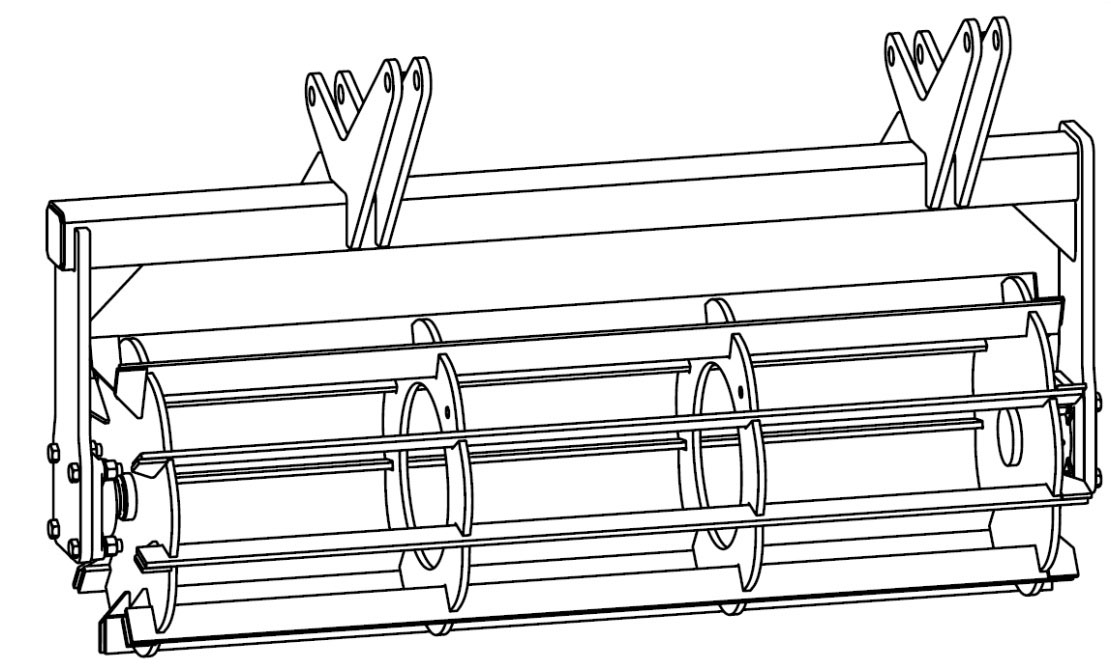

| The skating rink Veles-Agro is made of cast steel bases and edges are made of 10 mm boron steel alloy welded to the base, without a central shaft. The lack of a central shaft promotes the free movement of soil without clogging rink. | Rollers, with a central shaft and ribs, from the corner often clogged with soil. In processing the parched soil skeleton bent corners of the rink. |

|

|

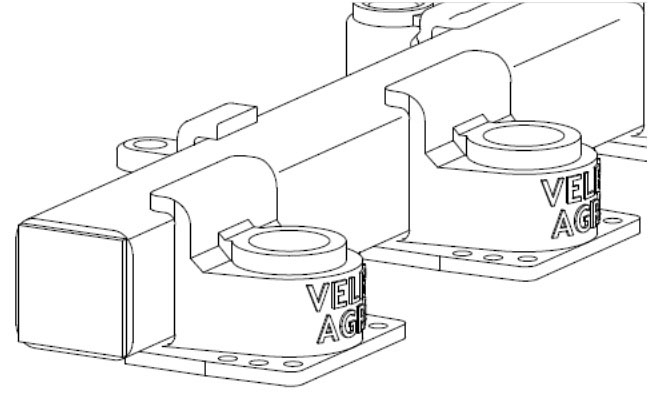

| Roller bearing assembly is manufactured in molded case with gaps freewheel body. Bilateral seal cuffs and grease fitting for lubrication. | It uses the standard box-type bearings UCF-209 without the dust cup. |

|

|