VELES-AGRO

tillage equipment and spare parts

Advantages of cultivator KPG series manufactured by LLC «VELES-AGRO LTD» in confront of others.

5 march 2015

The main features of cultivator work — tillage of the soil on settled depth layer prevents the evaporation of moisture

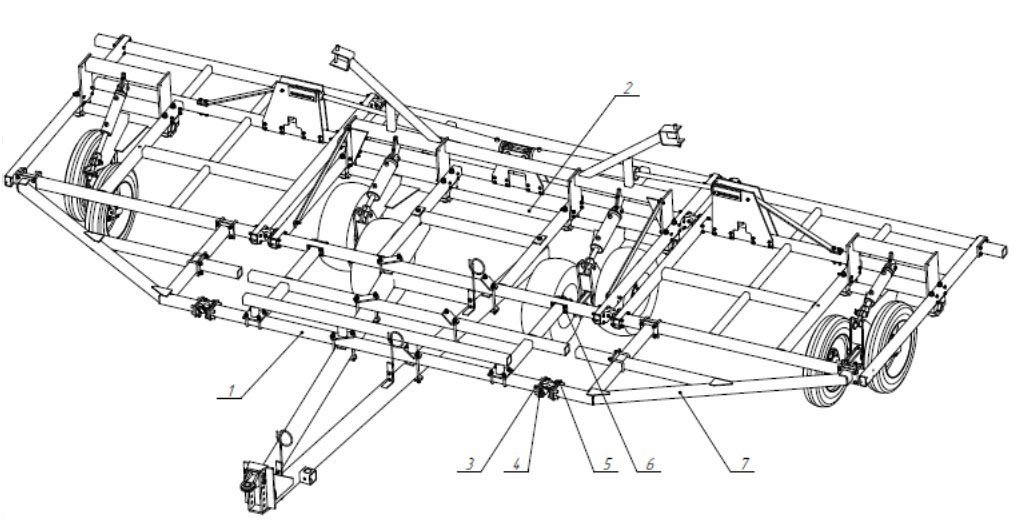

1. Frame construction.

1.1. Frame structures made of high-grade steel pipes S355JRH. Pipes are qualitative indicators factor «rigidity-flexibility» and allow easy design of frames without loss of rigidity.

1.2. Welding sections of frame structures occurs in the conductor to eliminate leashes metals and compliance with the correct geometry sections.

Welding is carried out in inert gas production on the German wire welding machines.

Painting is done on an automatic line of German manufacture and paint made in Germany, which allows for the guarantee of painted parts up to 10 years. Before painting is shot blasted, degreased and phosphatised.

1.3. When welding pipes, the company uses locks for alloy welds diversity, increasing their length without reducing the stiffness of the pipe itself.

Analogues cultivators for the indicator «rigidity-flexibility» clutter cultivators pipes 100x100, 120x100 mm, thereby weighing the total weight of the machine. Some manufacturers carry out welding work on the desktop, which leads to irregular geometry products. Some manufacturers carry out welding work on the desktop, which leads to irregular geometry products.

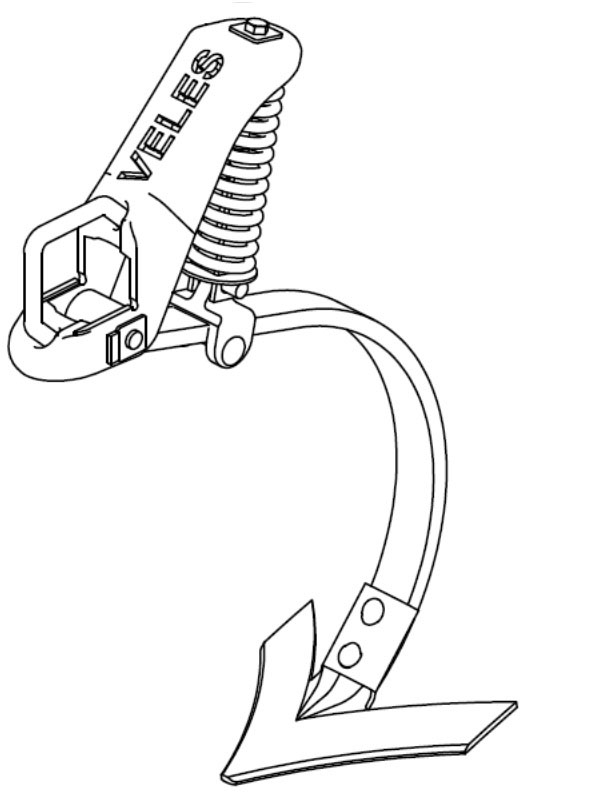

2. The working body of the cultivator KPG has a number of features which make it competitive capacity in comparison with other, namely:

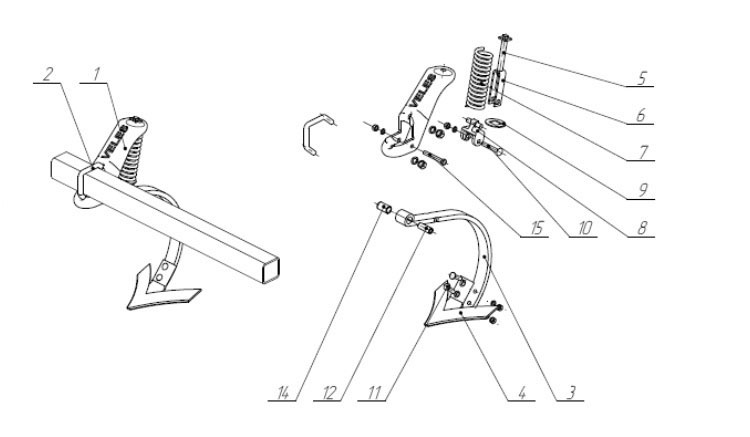

2.1. General view of the working body of the KPG

2.2. Chisel of working body cultivator KPG with variable widths arrows (220?330 mm) has an optimal angle loosening the soil and cropping crop residues. Made of durable boron steel. Cutting edge chisel forged, making more durable metal in this part.

Existing analogues

Not always set foot correspond to domestic soils and conditions of use.

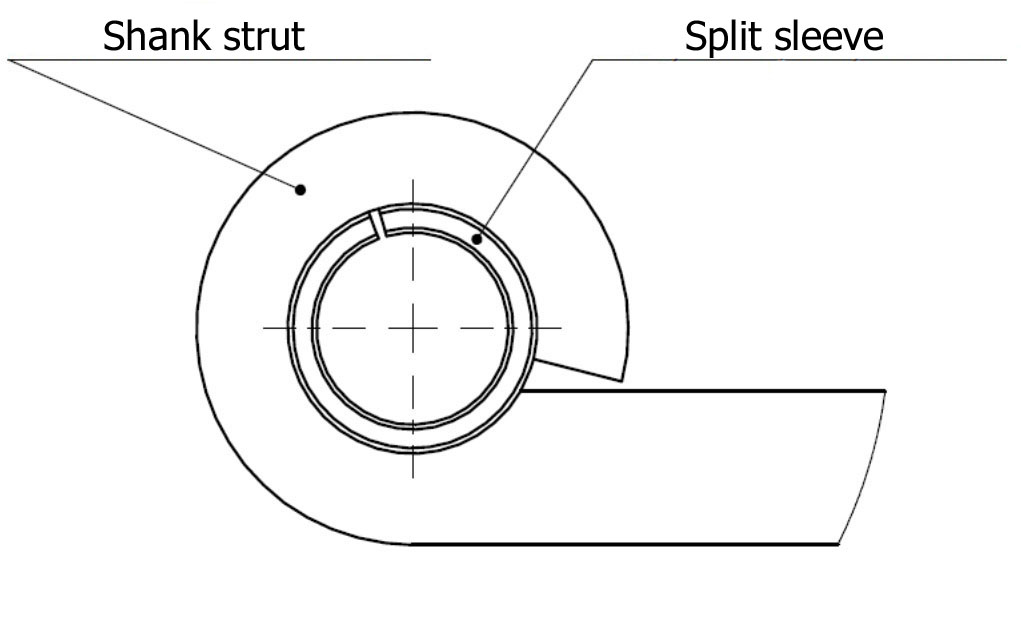

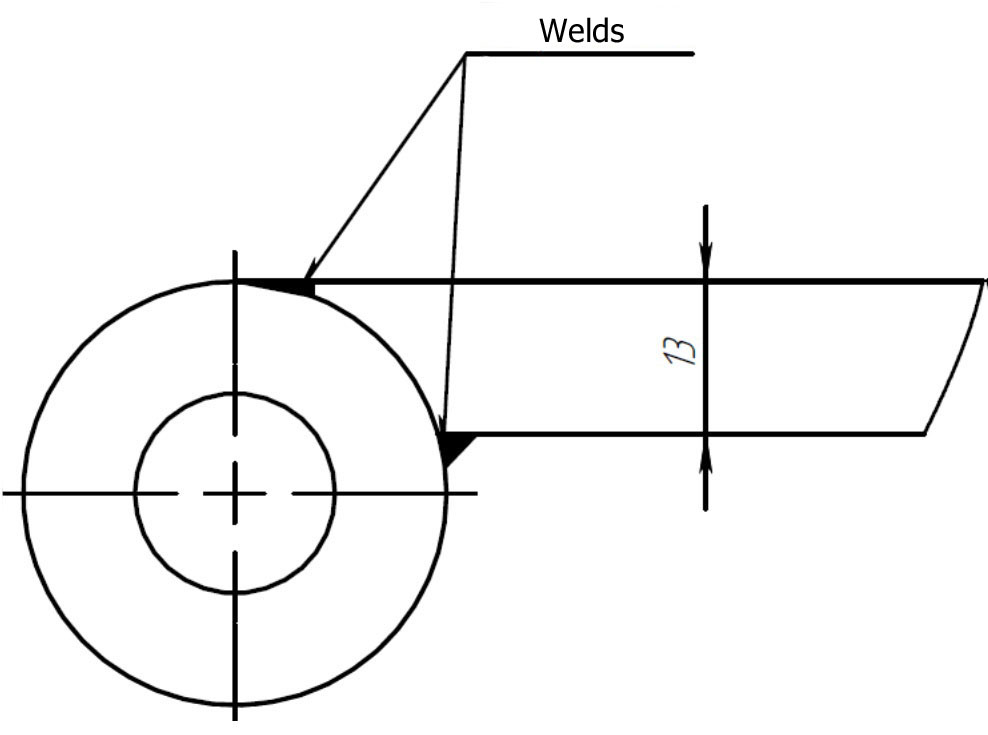

2.3. Front working body is made of boron spring strips have high strength and spring characteristics. In rack mounted shift quickly replaceable sleeve that prevents the degradation place mounting, thereby increasing resource exploitation entire unit.

| Node production Veles-Agro | Front cultivator Case |

|

|

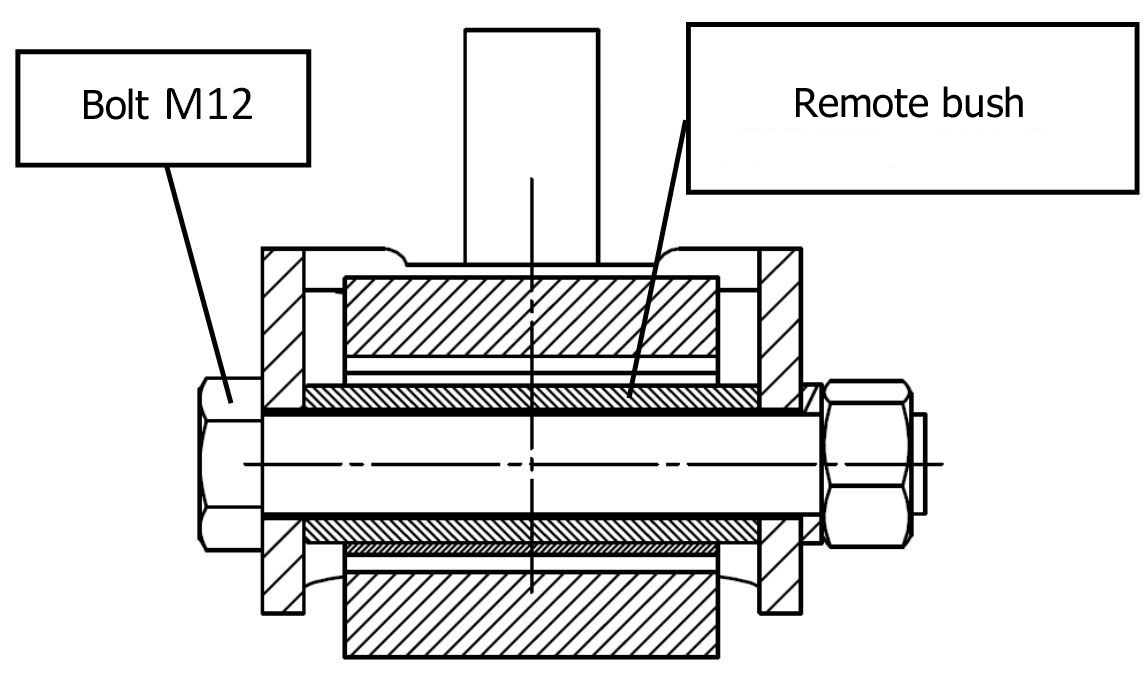

2.4. Finger mounting rack red-hot, and the combination of hardened fingers and cutting wear sleeve makes this a couple of reliable node. Finger has lock against rotation.

| Node production Veles-Agro | Node cultivator John Deere 960 Series |

|

|

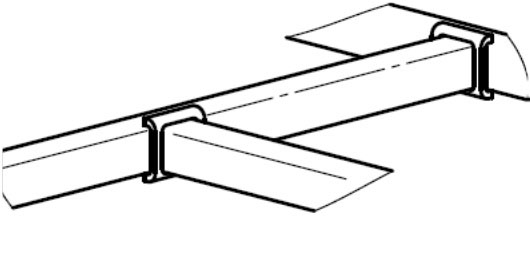

2.5. Mounting bracket working body to the frame of the unit is made in the form of cast steel parts covering the frame on both sides. Fastened by a bracket bracket M16. The wide contact surface of the bracket to the frame eliminates backlash bracket on the frame.

Recovered cultivators are not always equipped with the original struts, leading them to the strain at work on solid backgrounds. Not all similar cultivators have replaceable sleeve mounting rack — with wear seat is necessary to replace the entire rack. Incorrectly matched pairs lead to further deterioration and replace both parts of the unit

n similar units are often used forged or welded constructions brackets — less strong and measurable deformation loads.

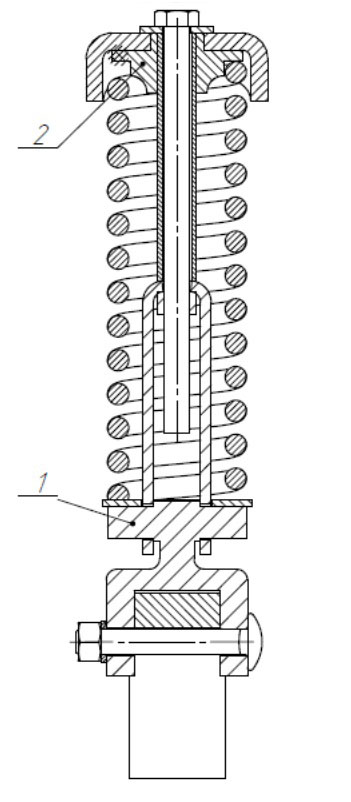

2.7. Node depreciation and safety combined in the overall design. With this assembly being installed precise horizontal position the clutches. In case of contact with minor obstacles there is an operation amortization spring. When critical loads organ system operates safely cutting screws, and the working body itself is not damaged.

2.8. Fixing the working body on the beam frame 80x80 mm, allows him to freely set anywhere on the frame, varying the width of the paw or the number of working bodies.

Existing analogues does not always work site safety in consequence of that is out of order all the working body. Not all analogs have the possibility of free placement of workers on the skid.

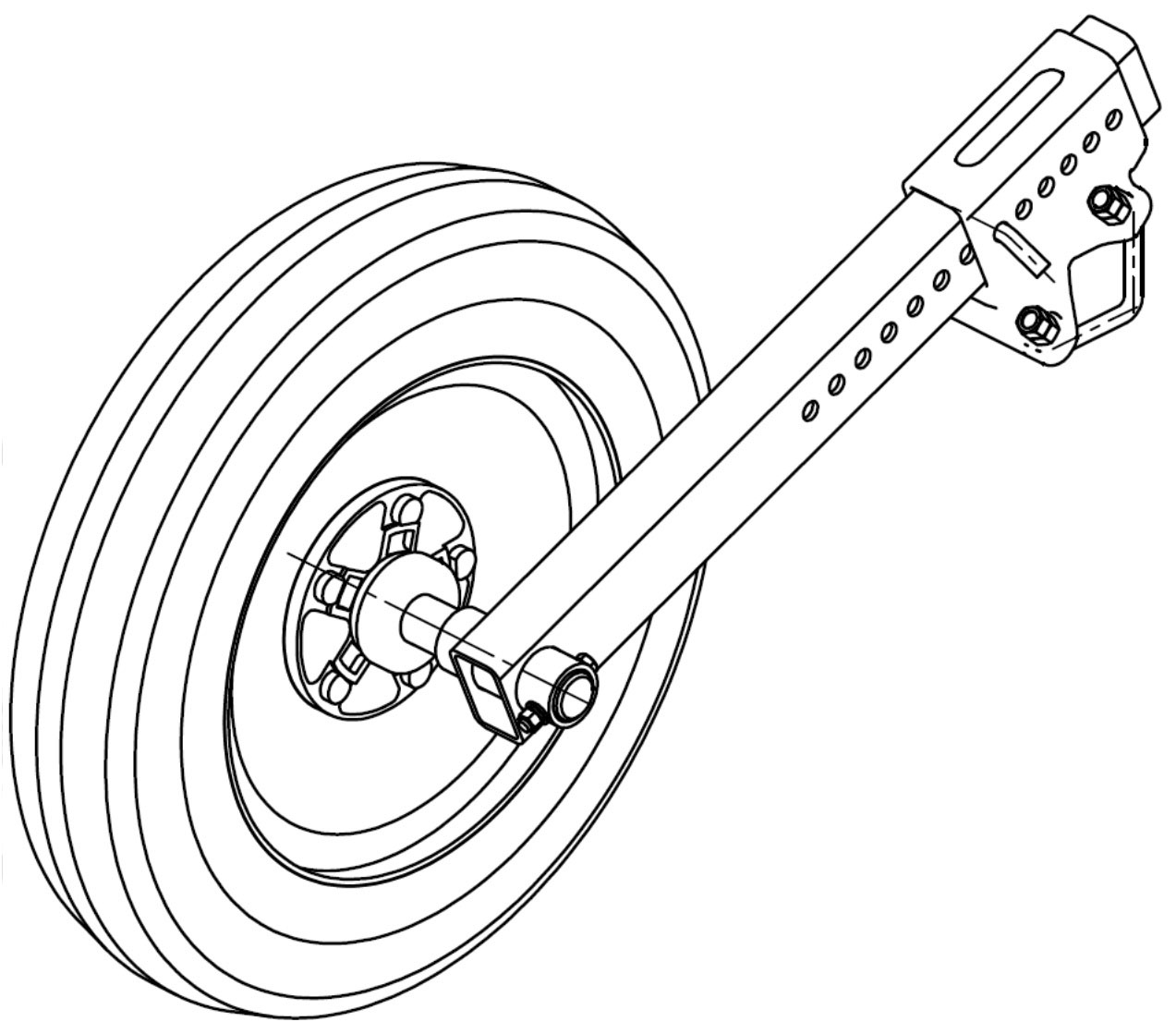

3. Support wheels.

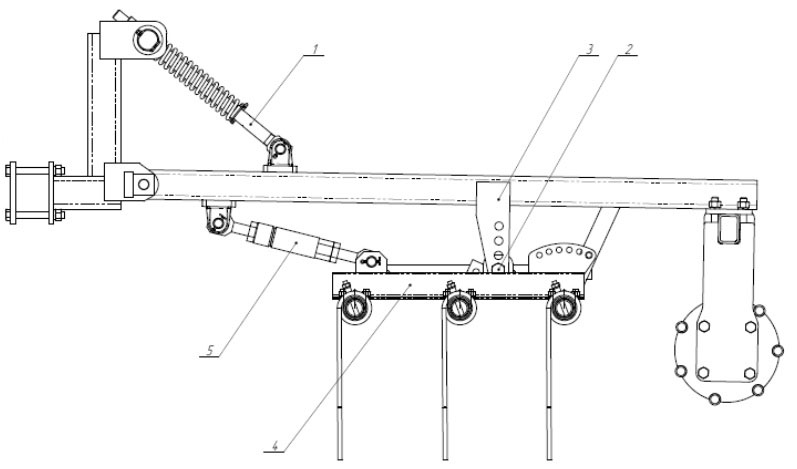

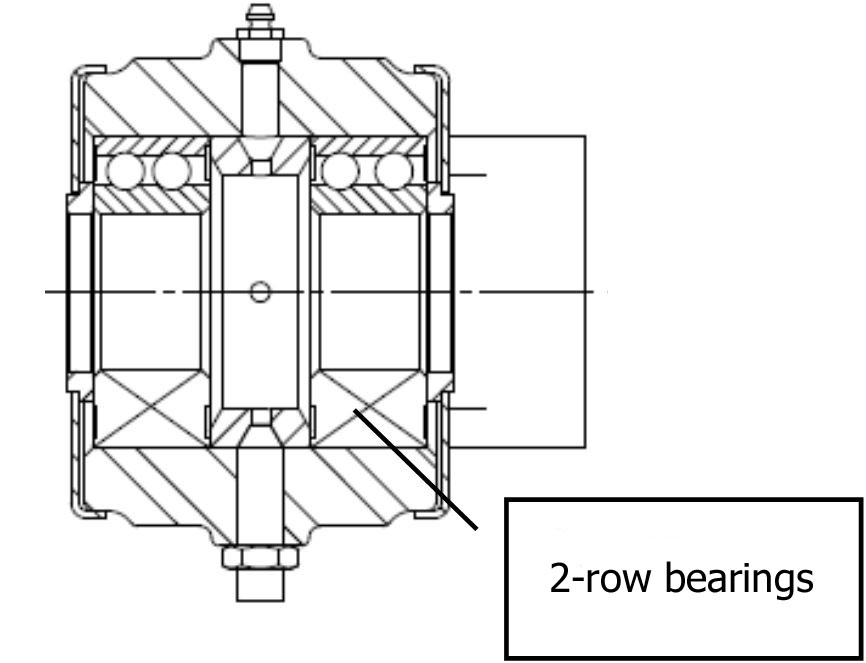

3.1. upport wheels of the central section of the cultivator are pendulum mechanism that allows tandem wheels exactly replicate the work surface and clearly resist cultivation depth.

| Tandem wheel center and side sections | Node tandem axle (suspension on the transport axis) |

|

|

3.2. The wheels of the side sections have a mechanical cultivator step adjustment. Simply migrated to the desired position. Easily adjustable to different beam frame (forward, backward)

3.3. To adjust the depth of a given treatment in the cultivator used floor restraints stroke hydraulic cylinder.

4. Rick and rollers

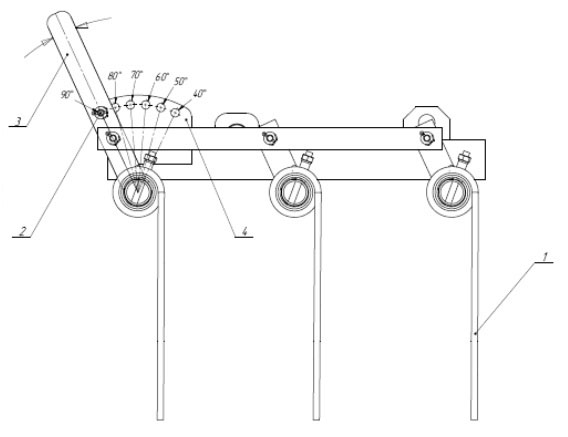

4.1. To align the surface to be treated, weed control and the creation of a finishing layer of soil mulch standard cultivator enabled 3-row spring comb with the ability to adjust the angle of the teeth.

4.2. In combination with a comb function tillage carries a small cage roller. As useless it can be easily dismantled.

Often used simple harrow or their analogs.

Not always equipped with this feature, such harrow tines can not be set at a certain angle of attack.